Following several aircraft accidents and inflight smoke and fire events, Aviation Accident Investigators have specifically cited the need for improved training to ensure adequate recognition and repair of potentially unsafe wiring conditions. Subsequently, both FAA and EASA have both adopted the training requirements developed by the National Transportation Safety Board (NTSB).

EWIS (Electrical Wiring Interconnection System) Initial and Continuation Training is now mandatory in order to comply with the training requirements covered in FAA Sections 121.375 and 129.14 of 14CFR and/or by EASA paragraphs 21.A.145 and 21.A.245 of Part-21, 145.A.30 and 145.A.35 of Part-145 and M.A.706 of Part-M.

The EWIS Training includes the following modules:

About the Course:

This course is online self-paced study produced by InfoWERK of Innsbruck Austria. It is based on EASA regulations as derived from ICAO standards and thus equally applicable to FAA and all other major national authorities.

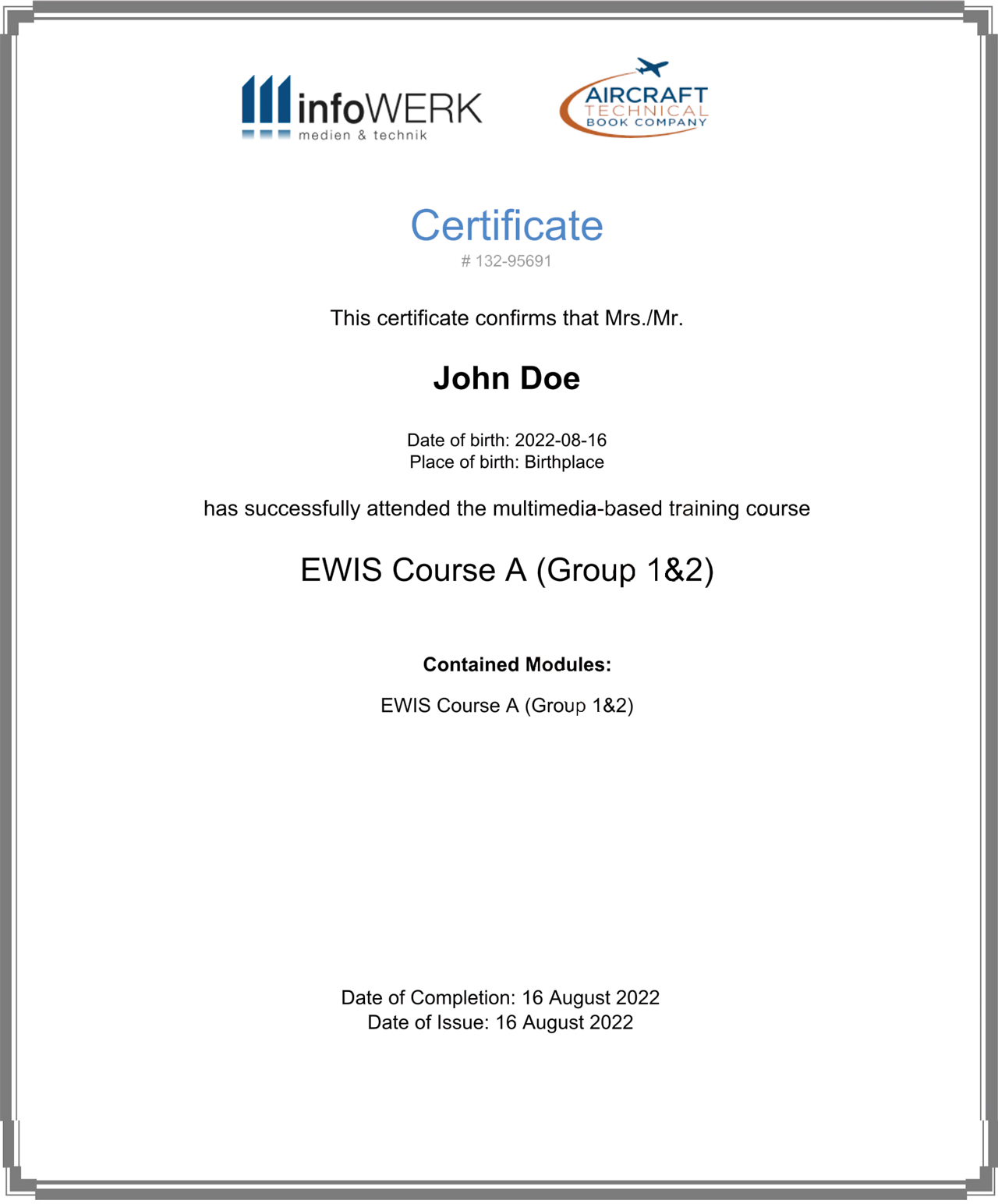

This course is built into short 1-2 minute segments including animations, video and complete narration. Stage exams provide a refresher and confirmation of the key points. A menu bar provides easy navigation between topics. The average time spent to follow and complete this course is 8 hours. The course ends with a final exam which when passed, provides a printable certificate of completion in your name.

Your enrollment in the course lasts for 1 year from the date of purchase. There is no limit to the number of times during that year that you can return to complete and refresh the course.

IA Renewal Credit

This course (FAA ALC-1148) qualifies for 8 hours of IA Renewal Credit. If you hold Inspection Authorization (IA), this course serves as the entirety of your annual continued training requirements. Upon your successful completion, ATB will authorize this credit through FAA and a printable IA certificate of accomplishment will be made available at www.FAAsafety.gov.

FAAST AMT Award Points:

In addition, this course qualifies for 8 FAA FAAST AMT Award Points, which will be issued upon your successful completion. To receive this award, you must have an account with FAAST. If you are not yet a FAAST member, your free registration can be found at www.faasafety.gov/login/reg/register.aspx

For Training Managers:

Self paced training is a great option for your continued and recurrent needs. It is economical, efficient, and allows your team to proceed on their own or during their down times, thus without the need to pull them away from the job. Contact us to discuss ways to integrate this method into your training programs.

This course is an interactive multimedia presentation developed by infoWERK. You are purchasing a license to use this course for a period of (1) one year. During this time you may use and review the course from any internet-connected device by logging in with the username and password which will be auto-generated when you complete your purchase.

After your purchase of this infoWERK multimedia course, you will receive (3) three emails. The first will be your order receipt with the subject line "Thank you for your order" which contains your order details. The second (2) two emails will be from infoWERK; one with your username and a link to the course, the second with your password (these are sent separately for security). Each of these emails will occur within moments of completing your order, if you do not find these email messages, first check your spam folder. Please keep these emails in a safe place for your future reference.

When you first open the course you will notice a menu icon on the bottom left of the browser screen. This menu will allow you to quickly navigate to any chapter of the presentation at any time. However, we strongly recommend proceeding with each topic in the order presented.

A certificate of accomplishment becomes available to download upon completion of the course and passing the final exam. The course becomes complete upon completing all content and passing each chapter exam.

Click To Enlarge